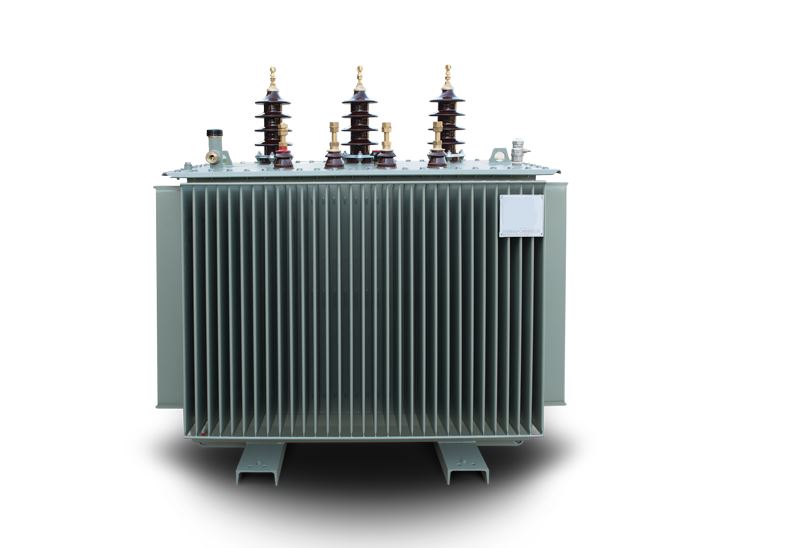

TRANSFORMATORE (35kV)

Description

DISTRIBUTION TRANSFORMERS

1. PURPOSE

This specification covers 6 / 0.4 transformers; 10 / 0.4; 20 / 0.4 and 35 / 0.4 kV for indoor and outdoor use.

1.1 EARTHQUAKE SYSTEM

1.2

TM 35, 20, 10 and 6 kV system: With insulated neuter.

0.4 kV TU system: Direct earthed ground

1.3 LEVEL OF ISOLATION AND SPACES

work provided in outdoor installations between insulated equipment and IEC standard for spaces.

The discharge distance in the insulator and the plate should not be less than 25 mm / kV in the system with higher voltage for external devices.

2. DESCRIPTION, REQUEST AND DATA FOR TRANSFORMERS

Distribution transformers are oil-filled hermetically sealed ONAN transformers.

Transformers have a nominal voltage value of – / 0.4 kV.

The voltage regulator that is placed on the TM side will be plus-minus 5% with 2.5% on each scale.

The link group will be by fact or request.

The TM and TU outputs of the transformer are for cables.

Power transformers are built in such a way as to meet the following requirements:

a. Quality to withstand any shock during transport and installation

b. Provide efficient heat distribution

c. Be waterproof and hot oil

d. Noise and vibration up to a permissible level.

2.1 Transformer core

The construction of the magnetic circuit is such as to avoid the development of static short-circuit discharges in the inner contour or in the earthed fixing structure and the production of the flow component perpendicular to the unpolished steel sheet.

The magnetic circuit is grounded by means of a removable test connection with the metal construction, which is placed in a favorable position.

The transformer core is made of high quality steel with oriented crystals. Nuclear composed of laminated steel sheets and each laminated sheet is insulated with suitable varnish to avoid losses from fuko currents

The nucleus will be supported at the base by insulated fasteners and grounded through a removable connection.

The nucleus (sheet metal sheets) is protected from corrosion by being coated with a layer of varnish with a thickness of at least 1mm.

2.2Peshtjellat

Transformers will have high-conductivity copper electrolyte windings or aluminum windings. The insulation material will be Class A (IEC 76-2).

Spiral insulation and connections will be free from insulation composition to soften shrinkage or shrinkage found utilization. The windings will be made of electrolytic copper or aluminum. In order to achieve resistance to short circuits by low voltage, the low voltage winding will be constructed with copper or aluminum strips instead of conductors. The transformer will have Class A insulation or better insulation. Wraps can be insulated with insulating paper or varnish in accordance with the manufacturer’s standards. The construction of the spirals will be such that a uniform distribution of impulsive voltages and discharge voltages is achieved, avoiding weak points in the insulation.

2.3 Transformer boiler

The transformer boiler is made of a material of such thickness and strength that it can be resisted without being damaged or overheated during working conditions or during short circuit. The transformer will be oil-free. For the boiler and other parts. The cooling system of the transformer will be with sheet metal on the side parts of the tank.

2.4 Voltage regulator

The voltage regulator is provided via a switch and will be placed in a convenient location (over the lid) to be easily maneuvered.

The voltage regulator is equipped with a regulating switch with external rotating handle that ensures the blocking of the regulator in the selected position.

The mechanism is located on the outside of the transformer for its maneuverability.

Positions corresponding to the adjustment value of the regulator are stamped or engraved on an indicator metal plate, fixed to the transformer cover.

The connection of the voltage regulator to the transformer cover eliminates oil leakage during its operation.

3.Transformer cable terminals

Transformer cable terminals are designed taking into account the type of connections described below:

• In TM: insulated aluminum cable

• In TU: insulated aluminum cable

The exit of the windings from the inside to the outside of the transformer is realized by means of transitional insulators made of brown porcelain. Insulators are for outdoor use.

4. Instruments and accessories

Transformers have the following accessories:

• Lifting hooks

• Tape at the top for oil filling

• Oil drain taps at the bottom

• Earthing bolts in diagonal position

• Wheels that move in two directions

• Target

• Voltage regulator switch

• Oil cap cap

• Metal mounting base

SPECIFIKIME

TECHNICAL SPECIFICATIONS

DISTRIBUTION TRANSFORMERS

1. DESCRIPTION, REQUIREMENT AND DATA FOR TRANSFORMERS

The 50-1000 KVA transformer is an oil-filled hermetically sealed ONAN transformer.

Transformers will have a nominal voltage value of 6 KV- 35 KV / 0.04 kV.

- TECHNICAL DATA

| Transformer 40 KVA three phase immersed in oil, | Unit | Price | |

| Nr | Transformer type | ||

| 1 | Applied standard | IEC | |

| 2 | Nominal power (Sn) | kVA | 50-1000 |

| 3 | Nominal voltage | kV | |

| 4 | Number of phases TM | 3 | |

| 5 | Connection group | ||

| 6 | Frequency | Hz | 50 |

| 7 | Limits of voltage regulation in TM | 2 x ___%; | |

| 8 | The grounding system TM | Isolated | |

| 9 | Low nominal voltage | V | |

| 10 | Number of phases TU | 3 phases/3 conductor | |

| 11 | The grounding system TU | Directly to the ground | |

| 12 | Cooling type | ONAN |

MAINTENANCE

- Transformer and Motor Power Repair Process:

- List of Transformers:

| TRANSFORMER TYPE | TENSION | ||||

| 6 kV | 10 kV | 20 kV | 35 kV | ||

| 1 | Transformers 50 kVA/ 3 phases | ||||

| 2 | Transformers 100 kVA/ 3 Phases | ||||

| 4 | Transformers 160 kVA/ 3 Phases | ||||

| 5 | Transformers 180 kVA/ 3 Phases | ||||

| 6 | Transformers 200 kVA/ 3 Phases | ||||

| 7 | Transformers250 kVA/ 3 Phases | ||||

| 8 | Transformers 320 kVA/ 3 Phases | ||||

| 9 | Transformers 400 kVA/ 3 Phases | ||||

| 10 | Transformers 560 kVA/ 3 Phases | ||||

| 11 | Transformers 630 kVA/ 3 Phases | ||||

| 12 | Transformers 1000 kVA/ 3 Phases | ||||

| 13 | Voltage transformers | ||||